Using LiDAR to spot Iron Mining in the Weald

The Weald lies in south east England, sandwiched between the North and South Downs, passing through the counties of Hampshire, Surrey, Sussex and Kent. Its name – derived from the West Saxon – means forest and in Old English woodland, indicating an abundant resource that would play a vital role in the historic metalliferous mining of the region. Underneath ancient forests, the form of mining has remained hidden to landowners until recent remote sensing advances have revealed the clues.

Iron ore has been mined on the Weald for thousands of years, with specific evidence of ironmaking dating back to 750 BC. The ore, in the form of siderite, occurs in patches or bands in the clay deposits that make up the geology of the area. These deposits were initially extracted by quarrying, and evidence of Roman-era opencast works still exist in the landscape today.

Tracing the Elements: Iron and Wood

Figure 1: Typical section of a bell-pit. The vertical shaft was dug to the ore bearing strata, before being opened out at the bottom to the limit of collapse.

During the Medieval period, extraction shifted from openworks to mine pits – which were typically five metres in diameter and up to twelve metres deep. This was a less destructive form of mining, as the spoil from one pit was used to in-fill the one before, allowing for the continued use of the land.In the western part of the Weald, the principal method of extracting iron ore was also the mine pit – however these pits were more like the familiar ‘bell pit’ (Figure 1) than the large excavations described above. These pits consisted of a vertical shaft up to 2.5 metres in diameter that would be sunk through the clay to the iron seam below. The bottom of the shaft would have been widened out to take as much ore as could safely be done, without the sides caving in. The pit would then be in-filled and another started a short distance away.

The abundant woodland that gave the Weald its name, also provided one of the vital ingredients for the iron working process: charcoal. Careful coppicing of the woods meant that the iron workers had an almost inexhaustible supply of fuel for their furnaces. The iron smelted in the Weald was used for everything from cannons for the army, household utensils and the railings that surrounded St. Paul’s Cathedral.

The visible remains of this industry are limited to the furnaces, forges and ponds that made up bloomery sites. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a bloom. Some 600 of these sites are known across the Weald and, according to The Wealden Iron Research Group (WIRG), it is possible to date about a quarter of the sites, with the majority developed during the time of the Roman Occupation (43-300 AD). Evidence of the mining itself is far more ephemeral. Often unrecorded on any detailed survey and of a transient nature means that identifying areas of historic iron extraction can be challenging.

Mapping the Ground

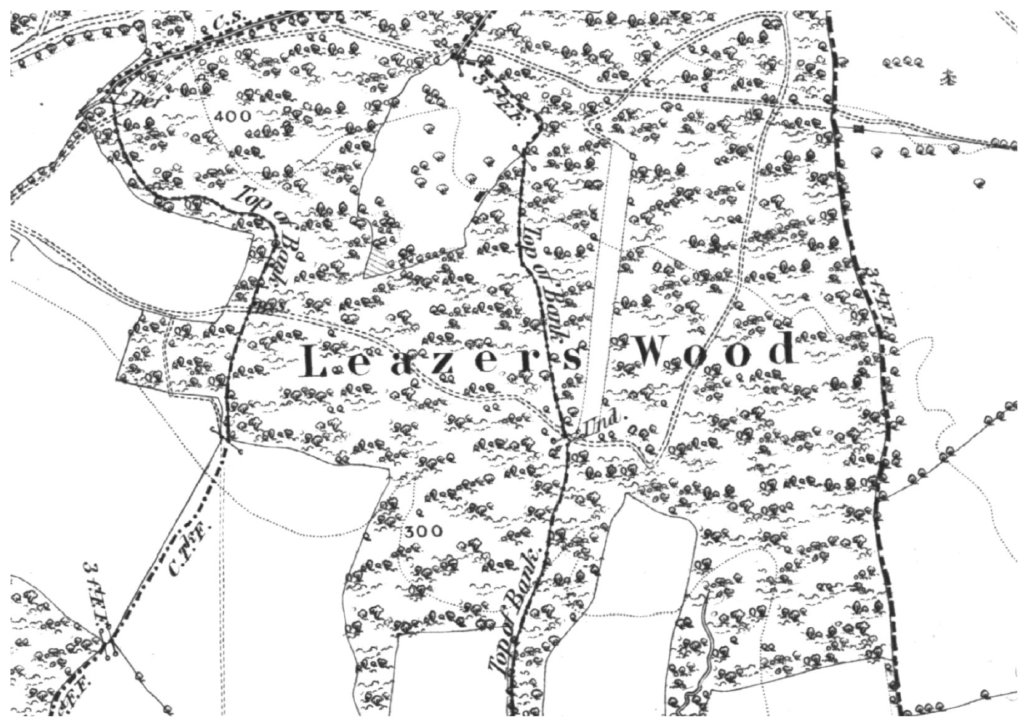

However, thanks to modern aerial surveying techniques, we can build a better picture of some of the more recent excavations. Take, for example, Leazers Wood near Chichester, West Sussex. This large mixed woodland is surrounded by arable farm land, with Fernhurst lying some distance to the west. An examination of the available historic mapping (dating from 1875-present, Figure 2) reveals very little evidence of change or industrialisation over the last 150 years. However, given the long history of iron extraction and processing that took place on the Weald, additional investigations are needed.

The underlying geology of Leazers Wood is Weald Clay – the strata that contains the iron ore that would have been the object of the miners’ interest. This, in itself, is not sufficient to raise any red flags: the presence of Weald Clay does not guarantee the presence of iron ore, or mining activity. However, the abundance of fuel (wood) and watercourses (used for powering later furnaces) within Leazers Wood, suggest that it may have been a prime site for iron extraction.

Historically the only way to confirm the presence of mine workings would have been an on- site investigation, in the form of a site walkover or intrusive drilling and trenching. Remote techniques such as aerial photography would be of limited use, owing to the canopy cover of the trees.

LiDAR: Stripping Away The Layers

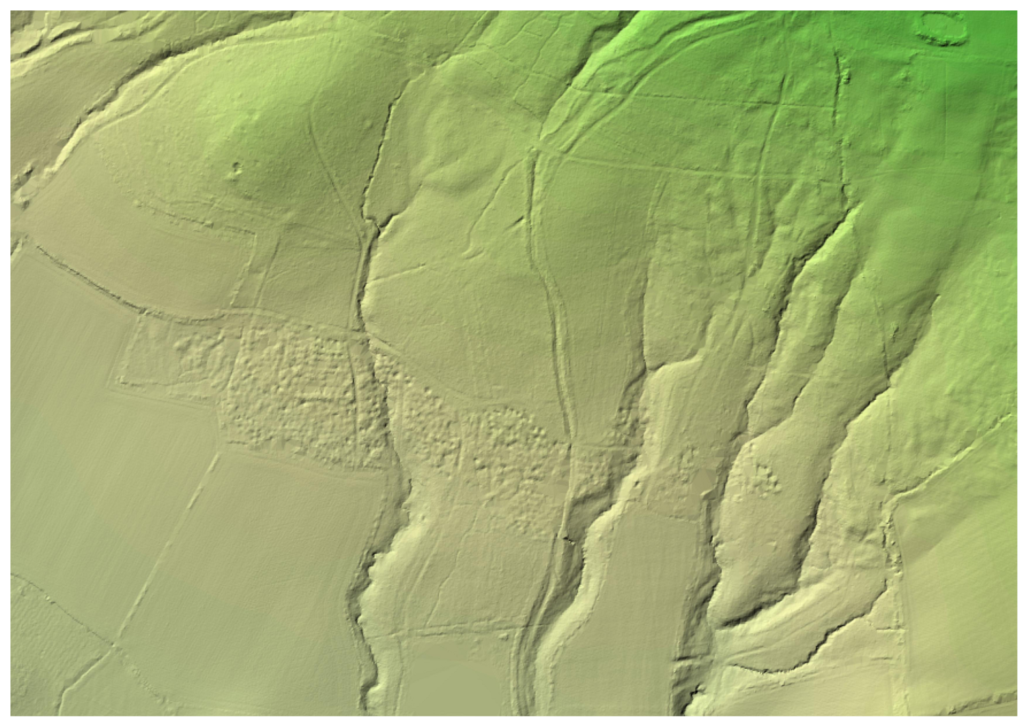

Figure 3: 2020 Digital Terrain Model (1 metre) Lidar Survey. Environment Agency, Open Government License. Extensive belt of mine pits passing through woodland.

With the advent of LiDAR (Light Detection and Ranging) surveys, however, we are now able to look beneath the trees at the ground surface below.

Figure 3 is an extract of the 2020 Digital Terrain Model (DTM) LIDAR survey, supplied by the Environment Agency. This model effectively strips away any features that are above the ground – trees, houses, bushes, etc – leaving a relief map of the surface on which previously obscured features are now visible.

Running through the centre of Leazers Wood, following a broadly west-east alignment is a belt of mine pits approximately 110 metres wide at its maximum. Figure 4 is an enlargement of the widest section, where it is possible to discern the closely clustered pits, in various states.

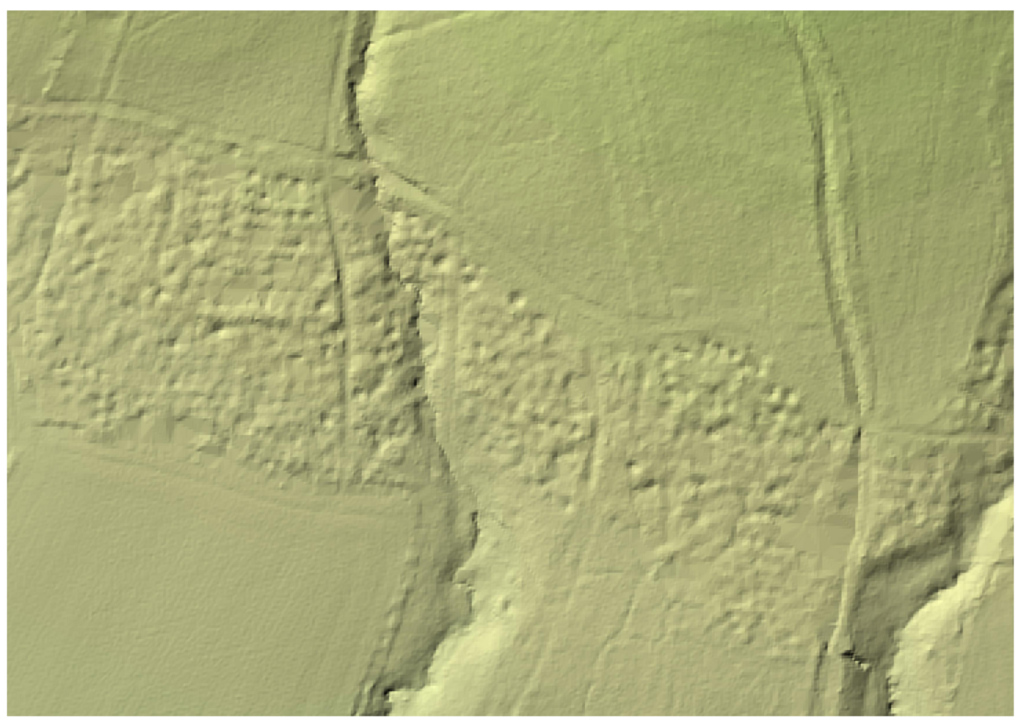

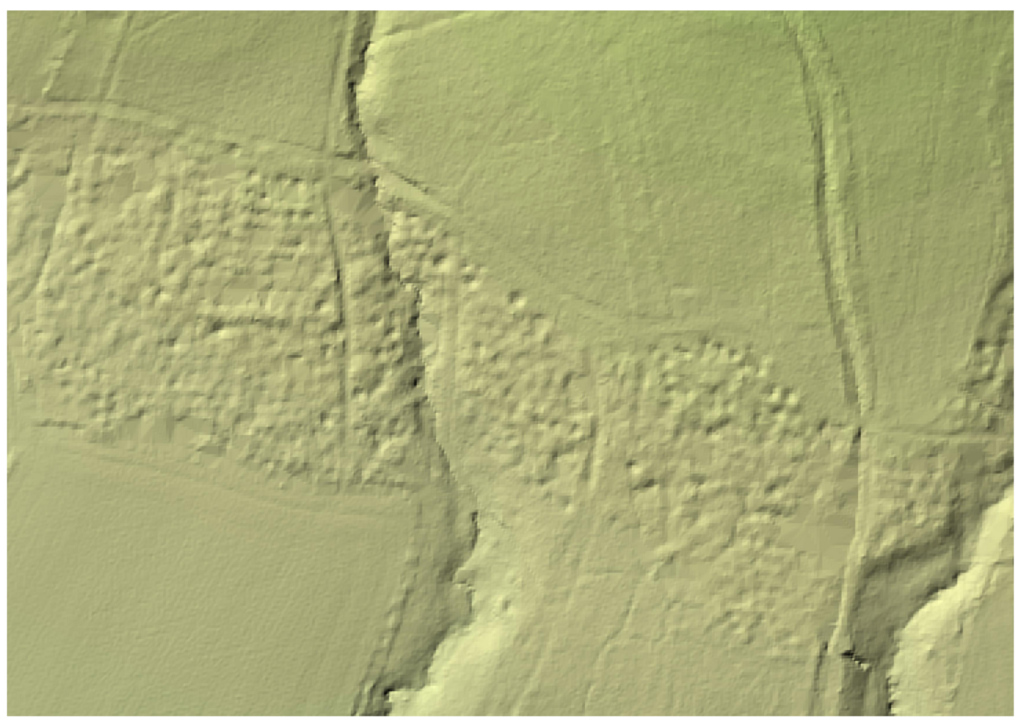

Figure 4: Detail of Lidar Survey, showing filled, partially filled and open mine pits.

Some are apparently in-filled to the surrounding ground level while others show evidence of fill settlement. Some of the strongest returns suggest quite deep depressions. The depth of these depressions can be obtained from a closer interrogation of the data, to within +/- 1 metre. The deepest of the visible mine pits have a depth of approximately 4.0 metres, demonstrating the gradual consolidation of the spoil used to historically fill the pits. Rendering the LiDAR data into a 3D model (Figure 5) highlights the pitted nature of the mined ground in Leazers Wood.

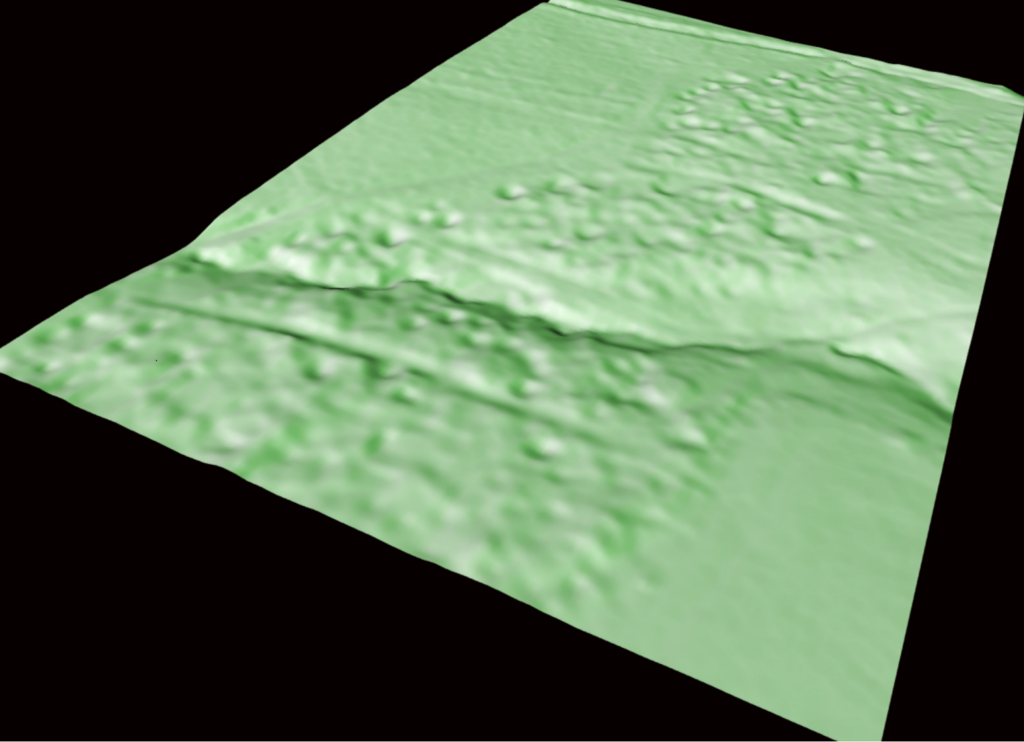

Figure 5: Rendering the Lidar data into a 3D model highlights the pockmarked, pitted nature of the mined ground.

Iron ore mining on the Weald, and the remote sensing techniques that can be used to examine areas of mined ground, or suspected areas of mined ground, provides a useful insight into other types of mining that have occurred in the UK.

Coal was extensively extracted in a similar manner where the seam was relatively shallow. The example of Leazers Wood helps to demonstrate the nature of features that have long been in-filled, levelled and built over across the coal field.

Additionally, the pit features highlighted by LiDAR are similar in nature to those in other metalliferous mining regions, like Derbyshire, where pits would be sunk along the course of a mineralised vein to locate and test its merchantable quality. If the ore was found to be sufficiently rich, it was from pits like these that underground mines would develop. Again, these features have been historically in-filled (as part of moorland reclamation), forgotten about and built over.

Capturing the Complete View

The Groundsure Geology team interrogates a wide range of historic maps, local archives , available LiDAR and 3D modelling to build a comprehensive picture of the sub-surface geology and past mining activity across the country. This insight can be accessed when and if specific queries are revealed from an environmental search report on behalf of a landowner or homebuyer.

To protect your client as part of their conveyancing searches, order an Avista report from Groundsure. Not only do you get ten environmental searches including contaminated land, flooding and natural ground stability, but past mining of ALL types including coal AND non-coal minerals like the Iron ore found in the Weald.

You can then access our expert mining consultancy team on your client’s specific site, property or development opportunity to see how it could be impacted, or indeed if any risk can be mitigated.

For more information about Avista contact us on 01273 277 755 or email us at info@groundsure.com

References

http://www.wealdeniron.org.uk/Expt/

Date:

Feb 18, 2022

Author:

Benjamin Oldcorn